Taking the lead in the industry to put forward the concept of special electric drive power assembly for electric loaders and put it into R&D trial production, the company has launched a high-speed two-speed electric drive system, which can significantly reduce the volume and weight of the electric drive system, free up a lot of cabin space, and facilitate after-sales maintenance. It also lays the foundation for future volume cost reduction. The system gearbox consists of an input shaft, an intermediate shaft and an output shaft, the gearshift device is arranged on the intermediate shaft, and adopts a 2-stage gear reduction structure, including a 1-speed gear pair and a 2-speed gear pair; the drive motor of the system adopts a 7,500rpm high-revolution motor, which can improve the vehicle running speed and decelerate the demand of the gearbox gears by increasing the motor speed;

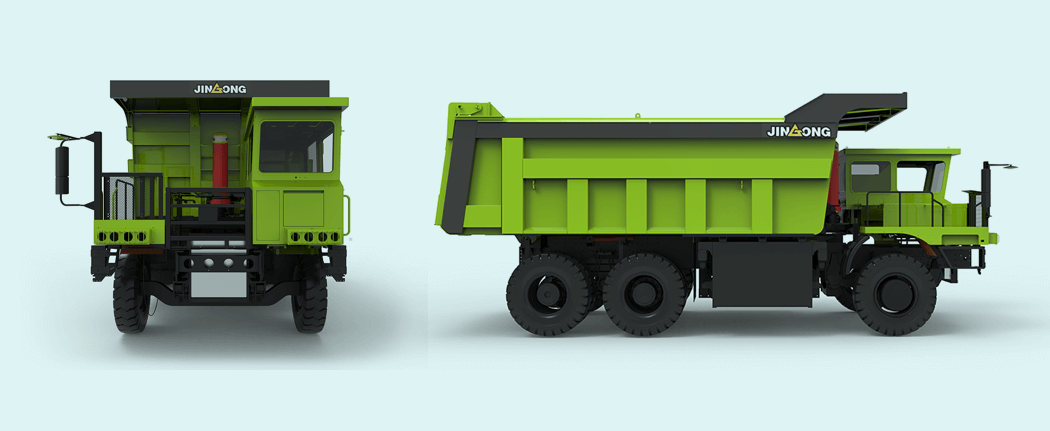

In the field of electric mining trucks, we have proposed a multi-power domain electric drive system solution. Through the modularization of power domains, multi-motor drive can be realized to enhance the upper limit of system power; each power domain is configured with 2 charging ports, which can realize 4-gun or even 6-gun fast charging;

Our company has started the development of hybrid power system for loaders, adopting high-power type super capacitor as the energy storage medium, high-speed two-speed electric drive system for chassis traveling drive, two-in-one integrated program of electric motor and electric control for bucket hydraulics, together with the intelligent hybrid energy management system software and other advanced technologies at the same time, to create the explosive products of the fuel loader in place of the fuel loader.