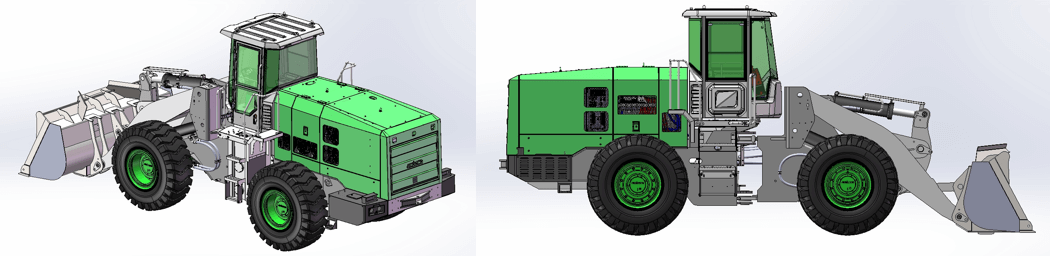

JGM series loaders

After 3 years of careful polishing and severe tests, the institute has launched the first long range, full working condition electric drive loader equipped with 350 degree battery 857E and 422 degree battery 867E in China, which has achieved excellent sales performance in steel mills, thermal power plants, mixing stations, mines, sand and gravel aggregate plants, etc. The 857E loader adopts our self-developed advanced electric drive chassis, which not only retains the reliability of the traditional chassis, but also has good expansion, compatible with multiple series of battery capacity arrangements, such as 350, 282, 210, etc. The 857E is equipped with our self-developed advanced electric drive chassis, which not only retains the reliability of traditional chassis, but also has good expansion. It not only retains the reliability of traditional chassis, but also has good expandability, compatible with 350, 282, 210 degrees and other series of battery capacity arrangement. The drive axle, the core of the chassis, is also strengthened and designed according to the characteristics of the electric drive, which greatly improves the load carrying capacity and driving torque; 857E loader adopts a 4-speed electric drive system, which has the largest output traction in the industry among the 5-tonne loader product series, and it has a more obvious advantage in stacking operation; at the same time, in order to increase the output per unit of time, the switching control of the forward and backward is also adopting a special strategy, and the driver can use the handle DR to control the forward and backward switching. The driver can use the handle DR to switch the fast braking and switch the driving direction; the hydraulic control system of 857E is matched with an independent 100Kw permanent magnet synchronous motor, which can realize the complete decoupling of the top-mounted hydraulic power and the chassis travelling power, which greatly reduces the waste of energy and improves the response of the hydraulic system; the bucket control system adopts the control strategy based on the target speed of the bucket, which can be controlled in real time by the driver through a single handle. The bucket control system adopts a control strategy based on the target speed of the bucket, which allows the driver to control the moving speed of the bucket in real time through a single handle;

Our company took the lead in the industry to put forward the concept of electric drive assembly for electric loaders and put it into R&D and trial production, and launched the 856E model, which adopts the industry's first high-rotation electric drive travelling system and hydraulic electric drive system, which greatly reduces the volume and weight of the electric drive system, releases a lot of cabin space, and facilitates after-sales maintenance. It also lays the foundation for lower volume costs in the future.

The Institute has been deeply engaging in the vehicle-electricity separation and power switching technology for loaders and commercial vehicles, and has designed various power switching structures, such as side-switching and top-switching.

In terms of electric loaders, we have developed and designed the industry's first field electric loader with autonomous power switching, which deeply integrates the power switching device in the frame, and only requires simple auxiliary operation by the driver to achieve field power switching without entering the power switching station, which greatly expands the market application space of electric loaders.