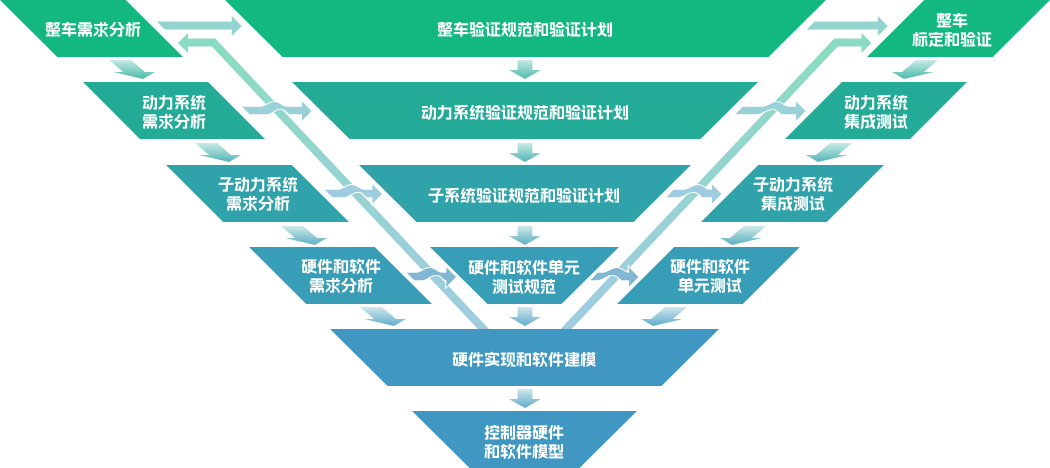

The company's software and hardware development team is proficient in new energy and engineering machinery and equipment electrical principles and control strategies, and has rich experience in the development of electric drive system control software and hydraulic control software; it has established a V-type development process based on the development of the model and organically combines demand analysis, system architecture, functional design, functional verification, simulation testing, and completes a variety of open control logic tests before the software on-board the bus, especially the response and protection tests of the control software in the event of signal failure, which greatly shortens the software validation cycle and improves the safety, development and testing efficiency of the software.

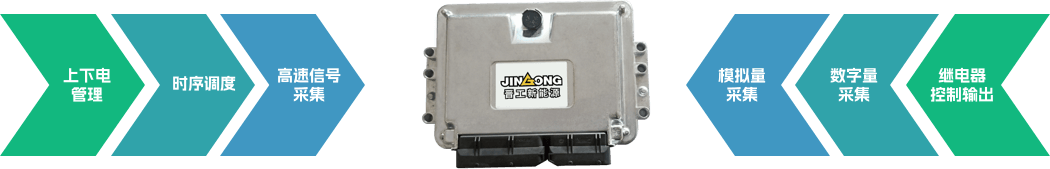

Our company independently developed and launched the 121-pin LVCU controller hardware, with upper and lower power management, timing scheduling, speed signal acquisition, analog acquisition, digital acquisition, relay control outputs and other commonly used functions of the vehicle controller, and at the same time in order to meet the demand for hydraulic control of construction machinery, the integration of the 12-channel solenoid valve PWM control channel, which can realize the high degree of integration of the hardware of the vehicle control and hydraulic control, and greatly improve the responsiveness of the chassis and the operation of the linkage performance;

Our company has independently researched and developed one-hand control system software and travel power control software to meet the needs of electric loaders, and has accumulated a number of technical patents in the areas of slip rate control, load recognition and overload protection, shoveling and transportation productivity statistics, energy destination statistics and management, as well as intelligent Internet connection.